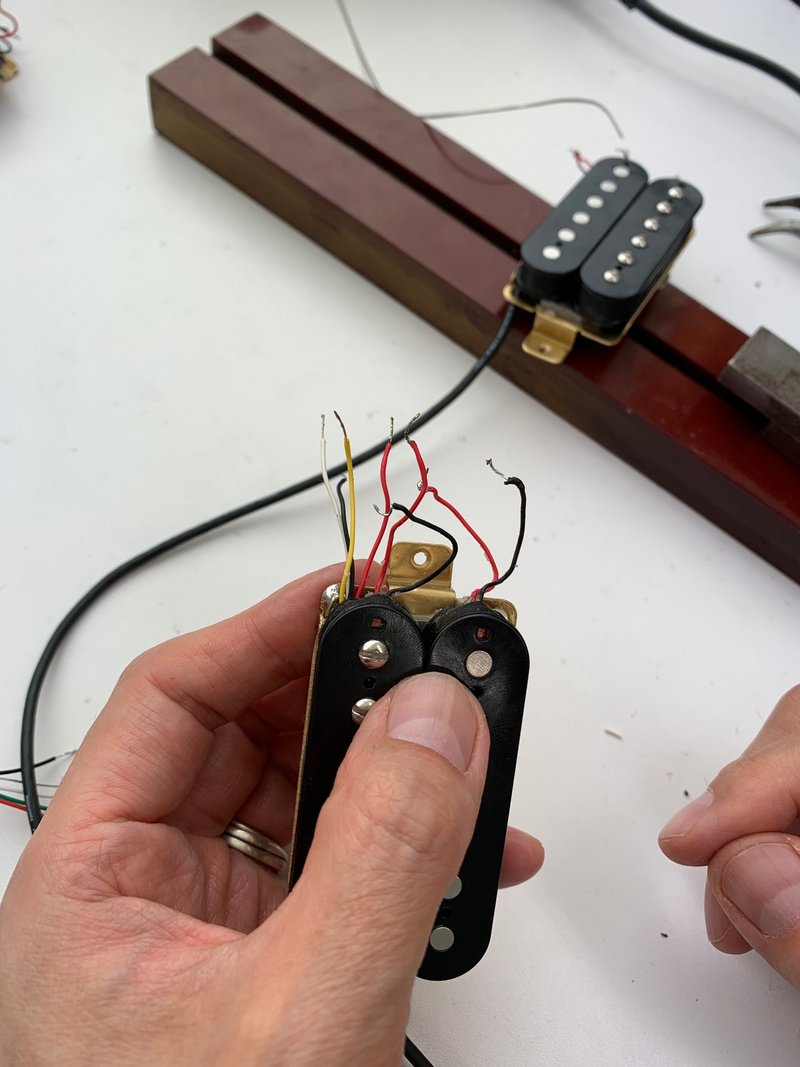

Pickup manufacturing begins!

(Note)

Before I was hospitalized, there was one thing I really wanted to be present for him to give me the pickup winding machine and teach me how to use it.

The eldest son, who is the representative of Nekodamari Kobo, heard that the president of a company that had been an important driving force behind electric guitars in Japan for many years had decided to retire and was planning to dispose of their equipment.

It was late September 2021.

He had been interested in pickup trucks for a long time and had been wondering if he could do something with them someday (although I didn't know), so he jumped at the chance and gave me two of them to start with.

The president who welcomed us was a very friendly man, with a kind smile and a considerate attitude.

They were surprised but happy that we had come as a family, and said it would be a good place to take a break! We were shown to a reception room lined with stereos and audio equipment, and it seems that it's a place where employees and friends have enjoyed karaoke for a long time.

The place used to be an office and factory, and I was generously taught a variety of things.

A female former employee whom the president had relied on for many years also came to help and gave advice on even the smallest details.

"Hey! This guy has great muscles! It's amazing that he's so good at it right from the start!" our factory manager praised him (laughs).

It was also nice to see how happy he seemed to be when someone called him "big brother," something he hadn't done in a long time.

The interactions between the president, the former employee, and his family (who were there to pick him up and drop him off) also revealed a good relationship, and it was clear that they were bound together by trust.

The president's carefree smile and playfulness were wonderful.

The office is a place where those bustling days feel like just yesterday.

Used equipment and tools.

I can picture in my mind the bright window panes with sunlight streaming in, the faded cushions on the chairs, the notes attached to the phone, the scribbles on the calendar, the worn floor in places, and the various scenes of people moving around there.

I felt as if I could hear the breathing of the people who supported that great era, and it left me with an indescribable aftertaste.

I don't know much about the pickup and other details, but I feel that I need to be prepared to accept the thoughts of the people who have lived here and the various histories that have been accumulated here.

It is definitely not something that should be treated simply as curiosity or taken lightly!

This must not happen!

I truly felt that I was glad to have been able to be there and experience this atmosphere firsthand.

I asked for a commemorative photo with the president.

I had a feeling that this would become a very important piece in history.

It was a beautiful day, and I'll never forget the fumes from Mount Asama that I could see in the distance.

The factory manager was originally a design engineer.

After graduating from high school, he got a job at a major general electric manufacturer where he learned the basics of design, and then at a major electronic parts manufacturer, he was drilled by part-time female employees into everything from soldering to assembly.

I never expected that the experience I have gained working overseas for several years as a technical instructor in order to transfer design functions overseas, and the experience I have gained working hard for many years as a design engineer, would come in handy here!

There is nothing that goes to waste.

I am so grateful that we can all face new challenges together as a family and help each other.

By Nekomama